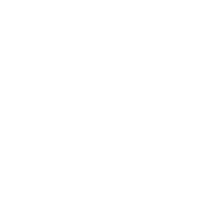

High Quality Rotary Parts Vibratory Feeding System Gasket Washer Vibration Bowl Feeder

1 . Descriptions:

To reduce production costs, enhance efficiency, and make products more competitive, adopting automated production is a key step—and vibratory bowl feeders play a vital role in such automated lines.

The primary function of a vibratory bowl feeder is to sort and position parts, preparing them for the next stage of production. In electronics manufacturing, where numerous tiny components require assembly, these feeders can accurately transport small parts to the next step without causing damage.

The functional design of a vibratory bowl feeder depends on factors such as the type and characteristics of the parts, production volume, and the required level of automation.

2 . Specifications:

| Product name |

Vibratory Bowl Feeder |

| Material |

Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller |

CUH,Sanki,Sinfonia,REO,Afag |

| Voltage |

220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power |

300W/500W/1000W/1500W/2000W |

|

Color

|

Green or Based on Customers' Requirement |

| After-sales Service |

Spare Parts and Technology Support |

| Warranty |

2 Years |

| Certification |

CE, ISO9001, ROHS |

| Lead Time |

3 Working Weeks |

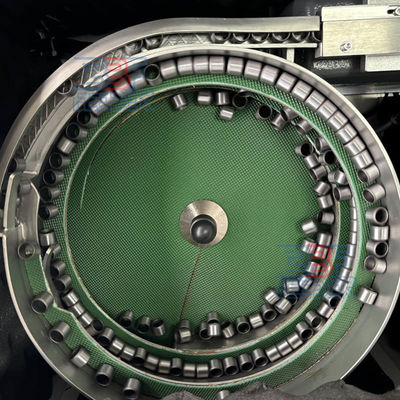

3 . Vibratory Bowl Feeders in Chip Conveyance

Vibratory bowl feeders are widely applied in chip conveyance, finding frequent use in industries such as electronics manufacturing and medical device production.

In electronics manufacturing, they are primarily used to convey and position small chips and components. Through the precise control of vibratory bowl feeders, chips can be accurately placed at designated positions, reducing manual errors and enhancing production efficiency.

In the medical device manufacturing industry, vibratory bowl feeders are utilized to convey small, precision electronic components. For instance, during the production of blood glucose monitors, these feeders can transport tiny chips and sensors to exact positions, improving the measurement accuracy of the products.

When using vibratory bowl feeders to convey chips, it is important to operate in a clean environment. To ensure both the feeders and chips remain clean, we recommend installing a dust cover around the vibratory bowl feeder.

4 . More Pictures:

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!